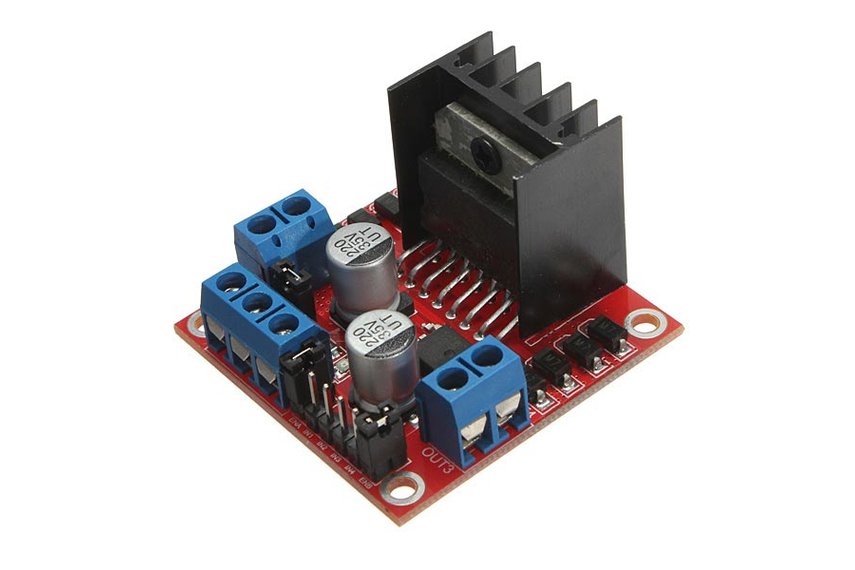

Stepper Controller Motor Driver module

L298N Dual Bridge

Product Code: MOT0375

$8.00

Pay it in 4 payments of $2.00 with

Product Description

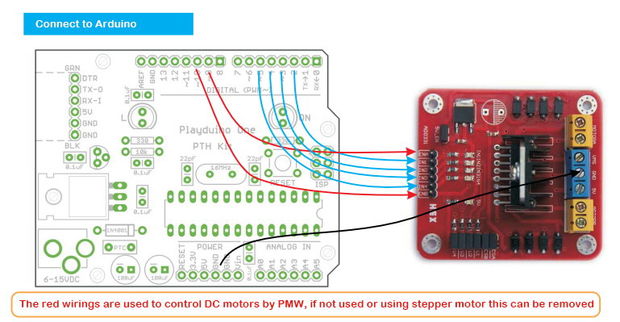

The L298N driver module, using ST's L298N chip can directly drive two 3-30V DC motor, and provides a 5V output interface can 5V single-chip circuitry to supply, support 3.3VMCU control, you can easily control the DC motor speed and direction, you can also control the 2-phase stepper motor, smart car essential.

Features:

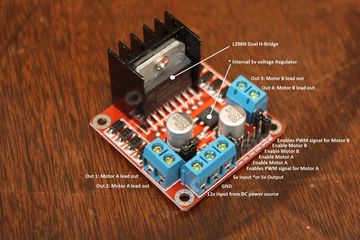

Driver: L298N Dual H Bridge DC Motor Driver IC

Driven part of the terminal supply area Vs: +5 V ~ +35 V; such as the need to take power within the board, the supply area Vs: +7 V ~ +35 V

Driven part of the peak current Io: 2A

The logical part of the terminal supply area Vss: +5 V ~ +7 V (can take power within the board +5 V)

The logical part of the operating current range: 0 ~ 36mA

Control signal input voltage range:

Low:-0.3V

High: 2.3V

Enable signal input voltage range:

Low: -0.3

High: 2.3V

Maximum power consumption: 20W (when the temperature T = 75 Deg C)

Storage temperature: -25 Deg C ~ +130 Deg C

Other Extensions: control of direction indicators, the logic part of the plate to take power interface.

Driver Board Size: 55mm * 60mm * 30mm

Drive plate Weight: 33g

Usage:

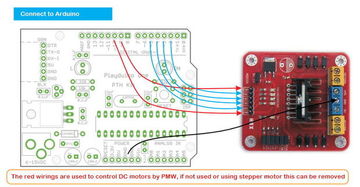

H-Bridge's are typically used in controlling motors speed and direction, but can be used for other projects such as driving the brightness of certain lighting projects such as high powered LED arrays.

How it works:

An H-Bridge is a circuit that can drive a current in either polarity and be controlled by *Pulse Width Modulation (PWM).

* Pulse Width Modulation is a means in controlling the duration of an electronic pulse. In motors try to imagine the brush as a water wheel and electrons as a the flowing droplets of water. The voltage would be the water flowing over the wheel at a constant rate, the more water flowing the higher the voltage. Motors are rated at certain voltages and can be damaged if the voltage is applied to heavily or if it is dropped quickly to slow the motor down. Thus PWM. Take the water wheel analogy and think of the water hitting it in pulses but at a constant flow. The longer the pulses the faster the wheel will turn, the shorter the pulses, the slower the water wheel will turn. Motors will last much longer and be more reliable if controlled through PWM.

Pins:

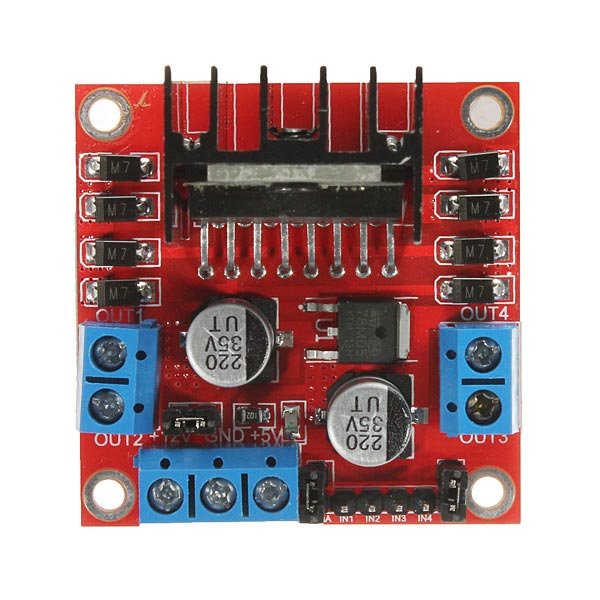

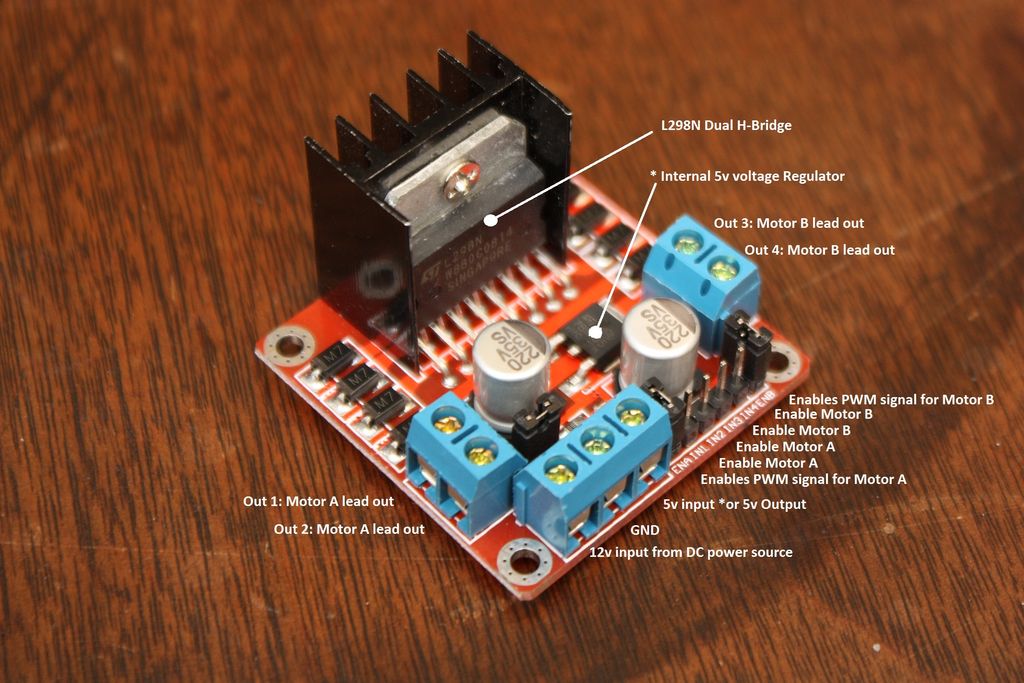

Out 1: Motor A lead out

Out 2: Motor A lead out

Out 3: Motor B lead out

Out 4: Mo (Can actually be from 5v-35v, just marked as 12v)

GND: Ground

5v: 5v input (unnecessary if your power source is 7v-35v, if the power source is 7v-35v then it can act as a 5v out)

EnA: Enables PWM signal for Motor A (Please see the "Arduino Sketch Considerations" section)

In1: Enable Motor A

In2: Enable Motor A

In3: Enable Motor B

In4: Enable Motor B

EnB: Enables PWM signal for Motor B (Please see the "Arduino Sketch Considerations" section)

*Built-in 5v power supply, when the driving voltage is 7v-35v

Manuals and Downloads

MODULE

The Bits that Count! Surplustronics sells masses of Arduino boards and other pre-made modules ready for your project. These come under the MODULE brand which is exclusive to Surplustronics. While much of this can be purchased online from overseas, we carry huge stocks right here in Auckland and your...